News Release from Weidmüller Monitoring Systems GmbH

Wind Industry Profile of

Caribbean flair for BLADEcontrol®

A particularly exciting project for the Weidmüller team was the repowering of the Fonds Caraibes – Quadran wind farm by POMA-LEITWIND. On Guadeloupe, 20 wind turbines from the early 2000s were replaced. Back in 2019, Italian wind turbine manufacturer LEITWIND developed a wind turbine with rotor blades that can withstand extreme hurricane force winds. This new LS39-H rotor blade was finally to celebrate its première on the French island of Guadeloupe.

"Warm and humid days, violent storms and a high salt content in the air are characteristic of the coastal location there and increase the complexity of this unique project. In light of these special wind and weather conditions, it is even more important to reliably detect damage and loads in order to be able to initiate appropriate measures at an early stage", is how the project team explains LEITNER AG's decision in favour of BLADEcontrol®.

Hans Reps, service technician at Weidmüller, accompanied the project on site

From India to West India

The complexity of the project was already apparent during the preparation of the quotation, in which we were always able to react flexibly to the requirements and wishes. The final decision was made to ship the BLADEcontrol® components separately, so that they could be installed in the wind turbine components at the respective LEITWIND plants in advance.

Our service technician Hans Reps showed great commitment in India. The installation of the blade sensors and training of the LEITWIND colleagues took place directly in the blade plant near Chennai. He and his colleagues from Germany, Tyrol, Spain and the Ukraine had to cope with the high temperatures in the morning. But the technicians on site were always helpful. They had a great time when Hans unexpectedly scared a green snake on the way to the rotor blade.

Despite the many different dialects from Europe and India, the blades were successfully equipped with our sensor technology according to schedule. Then they were shipped to the Caribbean.

Another challenge was the demanding schedule on Guadeloupe

During installation and commissioning on site, all work has to be carried out before the hurricane season. Unfortunately, the fickle weather does not adhere to forecasts. For example, the blades had to be temporarily stored during a typhoon. And due to restrictions on shipping, the large components of the WTGs as well as the erection crane could only be delivered by cargo ship at night. Thanks to the best possible and careful planning, new customised solutions and also thanks to the good cooperation with various suppliers and partners, POMA-LEITWIND and Weidmüller were able to successfully master all challenges.

Earlydamage detection through proven conditionmonitoring

The sensitive sensor system detects damage right from its initial stages. For this purpose, precise measurements are carried out in the natural vibration behaviour of the rotor blade. This type of detection detects even damage that is invisible from the outside and works reliably under all weather conditions.

Typical damage to the rotor blade includes blade tip damage caused by lightning strikes, trailing edge cracks, web separation and blade bearing damage. Only in the case of serious damage does BLADEcontrol® send a signal to the turbine control system, which can then stop the turbine immediately and prevent blade breakage.

In addition to direct damage to the rotor blade, operating deviations such as aerodynamic imbalances, loose parts in the blade and hub as well as pitch misalignments and yaw overloads are also detected. The system therefore makes an additional contribution to the operational reliability of the installation and helps improve the energy yield.

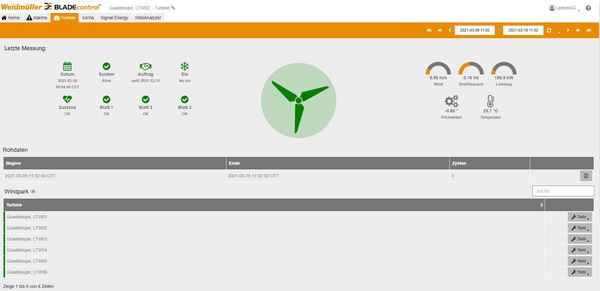

Illustration of the BLADEcontrol® WebVis interface in the LTW80 WEA2 on Guadeloupe

Web-based visualisation

All detected damage is simultaneously transmitted to the Weidmüller Monitoring Centre, where experts evaluate the data and prepare specific action recommendations for users. You can find out about the turbine status of the rotor blades at any time via online monitoring with WebVis.

BLADEcontrol® has been certified as an ice detector since 2008 and as a monitoring system for damage detection on rotor blades since 2013.

Successful cooperation worldwide

Projects like the one in Guadeloupe require close communication with all partners, detailed planning and a high degree of flexibility. This makes us all the more pleased and proud of this successful and friendly cooperation. The Quadran wind farm on the French Overseas Department is our first project in the Caribbean and has delighted all employees at the Dresden site. Especially in these times, wanderlust is particularly strong.

BLADEcontrol® is Weidmüller's solution for monitoring rotor blades. It continuously records the condition of each individual rotor blade and notices even small changes: around the clock, 365 days a year. As a result, problems are identified much earlier than with visual inspections, as progressing of damage in an uncontrolled manner is prevented. If damage occurs, this causes high repair costs, especially on an island.

- Source:

- Weidmüller Monitoring

- Author:

- Press Office

- Link:

- www.weidmueller.com/...

- Keywords:

- Weidmüller Monitoring, Condition Monitoring, BLADEcontrol®, rotor blade, wind turbine, turbine, Leitwind, Typhoon, safety