News Release from Brüel & Kjær Vibro GmbH

Wind Industry Profile of

We think out of this box!

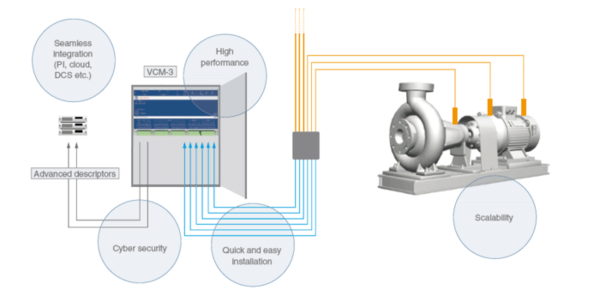

VCM-3 adds a new dimension of healthcare awareness to your assets, whether it be balance-of-plant, non-critical machines and even isolated critical machines. Compact, cost-effective, cutting-edge technology based on decades of expertise and a customer base of thousands of monitoring systems that are successfully watching over machines worldwide. As an optimal condition monitoring solution, it helps turn vibration into real business value.

Built-in expertise

VCM-3 is one step ahead of all other field devices. It uses specially defined measurements that not only automatically detect developing faults earlier, but also give a diagnostic indication on the type of fault and its severity. We packed over 20 years of condition monitoring experience in that little box to make your life easier.

High-tech throughput gives scalability

VCM-3 is among the most powerful data acquisition and processing field units in the market. And it’s cyber secure. It has been designed for scalability, so you can get started now with the basic model. As your experience and needs grow, we’ll be there to assist you with updates and enhancements.

IoT pathway to higher productivity

The system is designed to optimize machine healthcare to the highest, yet most cost-effective level. It will include future seamless integration with your existing historian, so you can use existing data management infrastructure without buying other servers. It also will include a cloud solution, where no client expertise or data monitoring infrastructure is needed at all. And we also offer services to help you every step of the way.

Data management and installation made easy

The built-in OPC UA server enables the VCM-3 data to be seamlessly integrated to your DCS, SCADA, data historian and other systems. In fact, VCM-3 is one of the easiest field devices on the market to install and commission.

VCM-3 can add a new dimension of healthcare awareness on your assets and help turn vibration into real business value. Visit our website or contact your local sales representative to find out more, including upcoming versions.

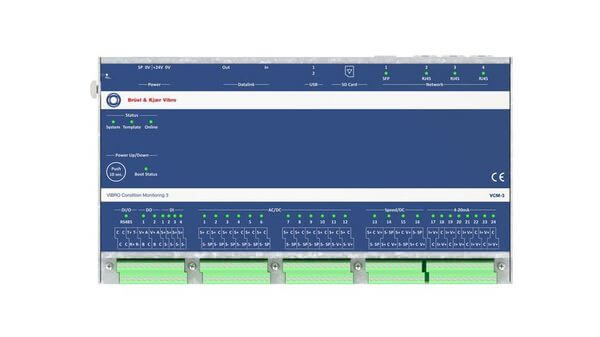

Basic model specifications

Physical:

- L: 280, W: 153.5, H: 35 mm

- DIN rail or wall mounting

Sensor inputs:

- 12 differential AC/DC

- Acceleration sensors

- Simultaneous channel monitoring/204.8 kHz sampling

Communications hardware:

- 3 Ethernet ports usable as switch

Communications protocol:

- Modbus TCP/IP

- OPC UA server (embedded in VCM-3)

VCM-3 homepage:

- Embedded Web server/User portal

- Measurement (descriptor) data display

- Time waveform (oscilloscope) display

- FFT spectrum/envelope spectrum display

- Source:

- Brüel & Kjær Vibro

- Author:

- Press Office

- Link:

- www.bkvibro.com/...

- Keywords:

- Brüel & Kjær Vibro, automatic, machine fault detection, diagnostics, model, specification, condition monitoring