News Release from windfair.net

Wind Industry Profile of

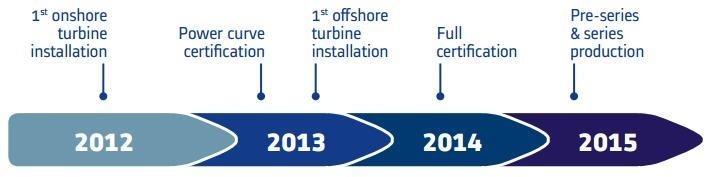

Product Pick of the Week – Alstom's Haliade™ 150-6MW Offshore Wind Turbine

HIGH YIELD, UNCOMPROMISING RELIABILITY

Building upon its ALSTOM PURE TORQUE® technology for reliability, Alstom has developed a 6 MW direct-drive wind turbine suitable for all offshore conditions. Proven technology and innovation are combined to deliver market-leading cost efficiency. The turbine incorporates dedicated offshore technology in collaboration with some of the industry’s leading component suppliers. There can be no compromises on a power-generating product that operates in the industry’s most challenging environmental conditions.

TECHNICAL OVERVIEW

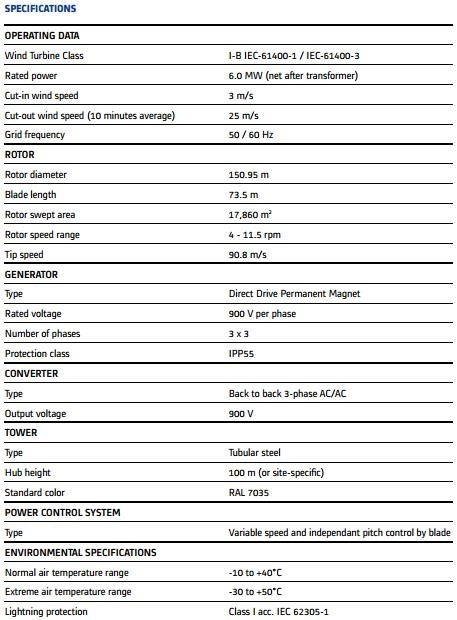

The Haliade™ 150-6MW is a threebladed wind turbine with a 150 m diameter rotor and a rated power of 6 MW.

The turbine has been designed following Class I-B specifi cations of the standards IEC-61400-1 / IEC-61400-3. It is suitable for sites with a reference wind speed of 50 m/s (10 minutes average) and a 50-year extreme gust speed of 70 m/s (3 seconds average).

The Haliade™ 150-6MW is equipped with a direct-drive permanent magnet generator and three identical full-power converters operating at 900 V each. This voltage is increased by means of a transformer included in the turbine. The inverter, transformer, switchgear and low voltage electrical distribution cabinet are located at the tower base.

A distribution cabinet in the nacelle supplies power and signals to pitch, yaw and cooling fans and collects signals from all system sensors. The wind turbine is air-cooled and pressurised. Construction materials and protection treatments are specifi cally designed for offshore environments. Heat exchangers and pressuring units prevent salty air entering while dehumidifi ers prevent corrosion of components inside the wind turbine.

INNOVATIVE TECHNOLOGY

Several design features ensure that the Haliade™ 150-6MW provides the highest possible yield in all circumstances.

• Failure tolerance for continuous production: 3 independent generation and conversion lines ensure uninterrupted operations

• Software-controlled de-rating strategies guarantee operation in the event of partial faults in the power line or cooling systems.

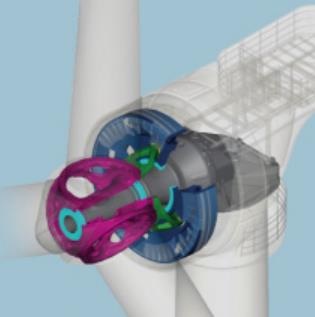

Haliade™ 150-6MW features ALSTOM PURE TORQUE®, a unique rotor support concept protecting the generator from deflection loads, to improve its performance.

The design separates the turbine rotor and generator to ensure that only turning force — torque — is transferred to the generator. This allows the minimum air gap to be maintained between the generator rotor and stator at all times, offering the highest electrical effi ciency.

RELIABLE

Alstom’s unique and proven rotor support technology with a direct-drive permanent magnet generator (PMG), provides outstanding reliability of the turbine’s drive train. With no gearbox coupled to the generator, the turbine consists of fewer rotating parts, which increases reliability, maximises turbine availability and reduces maintenance costs.

The use of a permanent magnet generator (PMG) leads to better generation effi ciencies and even greater overall mechanical reliability, which is critical in offshore wind.

The innovative “Advanced High Density” direct drive PMG is a more compact and lightweight design compared to earlier generation of directdrive systems.

EFFICIENT

Strength and durability are maximised in an exceptionally 73.5 m light blade uniquely developed for the Haliade™ 150-6MW. This new blade builds on the proprietary technology. Combined to the 150 m rotor diameter improves annual energy production by 15% compared to the current generation of offshore turbines.

The large diameter rotor added to the 6 MW rated power turbine maximises the capture of energy. An aggressive target weight eases installation and minimises the cost of both the turbine and supporting structures.

SAFETY FIRST

Alstom’s commitment to health and safety is uncompromising. The Haliade™ 150-6MW is designed to make maintenance as simple and as safe as possible:

• The hub can be accessed directly from the nacelle, allowing major service operations from within the turbine

• The nacelle is equipped with a 1 tonne capacity crane in the central frame

• A helicopter winching area allows for quick rescue in case of emergency at sea

OPTIMISED OPERATION AND MAINTENANCE

Modular approach

Alstom’s full range of services capabilities can provide everything from spare parts, repair, and on-site field services, up to and including long-term O&M solutions. It covers manpower and materials for both corrective, preventive and predictive maintenance. Alstom operates a global network of local service centres and offers a full range of packages and services with a fl exible approach to:

• Maximise availability

• Improve energy generation

• Optimise component and system lifetime Alstom’s fl exible offering uses both helicopters and vessels for the fast and safe transport of personnel and spare parts between onshore base, offshore base and wind turbines. Additional specifi c vessels are hired as required, for example when heavy lifting equipment must be used.

CONTROL AND MONITORING

Alstom has developped solutions to address both onshore and offshore requirements.

• WindAccess™: integrated control and monitoring which monitors and collects data from the wind turbines, meteorological mast and substation so that the wind farm can be operated like a conventional power plant

• Wind e-control™: a high performance real time system integrating wind farms into the most demanding grid codes

ALSTOM ADVANTAGE

Customers have already selected the Haliade™ 150-6MW for its advanced technology to equip their future offshore wind farms:

• In France, Alstom will install 240 turbines (1.4 GW) off the French coast.

• In Germany, KNK Wind has chosen the Haliade™ 150-6MW for the Arcadis Ost 1 project (58 wind offshore turbines in Baltic sea).

• In America, Alstom will supply the 1st offshore project in the US, Block Island project.

To receive more information on this article, our Newsletter or find out more about what w3.windfair.net has to offer, please, do not hesitate to contact Trevor Sievert at ts@windfair.net.

Please don't forget to follow us on Twitter: w3.windfair.net on Twitter

w3.windfair.net is the largest international B2B internet platform in wind energy – ultimately designed for connecting wind energy enthusiasts and companies across the globe.

- Source:

- Alstom

- Author:

- Trevor Sievert, Online Editorial Journalist / By Alstom Staff /

- Email:

- ts@windfair.net

- Link:

- www.windfair.net/...