Shaft Seal Seventomatic - Freudenberg Sealing Technologies GmbH & Co. KG

Wind Industry Profile of

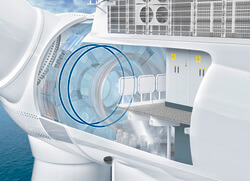

Shaft Seal Seventomatic

Freudenberg Sealing Technologies’ shaft seal “Seventomatic” is intended for shaft diameters starting at 1.5 meters. It uses a meander spring to build up the needed pre-stressing forces. The product gets its name from the figure “7” – a long sealing leg is linked with the stationary portion of the seal using a flexible joint.

The Seventomatic seal produces consistent linear forces and is less susceptible to shaft runout than other shaft solutions. In its standard size, the shaft seal tolerates a deflection of ±3 mm without a decline in its performance. As a result, it handles the shaft’s manufacturing tolerances extremely well. It is made from hydrogenated nitrile butadiene rubber, a material in the Ventoguard family of wind energy solutions.

The goal was to combine the special design of a seal for tunnel boring machines with the advantages of a classic radial shaft seal ring for the rotor’s main shaft. Comprehensive simulations made it possible to ensure a robust design in advance. When endurance tests with approximately 15 million load changes were run on samples, the engineers found neither identifiable damage nor limits on the Seventomatic’s capabilities. Other testing dealt with temperature changes between -30 and +100°C as well as stability during vibrations of 8 Hz with an amplitude of ±3 mm at 110°C. In addition, there was an investigation of the linear forces of mounted seals after 240 days of storage at room temperature and at 100°C.

The results showed that the new Seventomatic seal reliably retains the grease used in turbine roller bearings and is not susceptible to static and dynamic eccentricity while offering a constant linear force.

| More Images - please click to enlarge |

|