News Release from alki Technik GmbH

Wind Industry Profile of

World Champion of Height in the Wind Assembly

The highest wind power plant of the world and this even within the unique “Naturstromspeicher” (engl. green energy storage facility) in Gaildorf: When installing the wind turbines in this innovative pilot project, Max Bögl used the electric torque multiplier EF 300 Plus by alkitronic. The tool is easy to handle and even bolts difficult to access are no problem. So, the rotor blades could be optimally tightened.

COMPANY PROFILE

With over 6,000 highly qualified employees and an annual turnover of more than 1.65 billion euros, Max Bögl is one of the largest construction, technology and service companies in the German construction industry. Since 2010, the group has been active in the field of wind energy through its subsidiary Max Bögl Wind AG. Meanwhile it has become the market leader in manufacturing, delivering and installing hybrid towers.

Naturspeicher GmbH, a subsidiary of the Max Bögl Group, is responsible for the pilot project of the green energy storage facility in Gaildorf.

INITIAL SITUATION

The idea of the worldwide unique power plant concept which is called “Naturstromspeicher” was already developed by Max Bögl in 2011. Electricity generation and electricity storage should be combined in an innovative way within this project.

The innovative green energy storage facility: Four wind turbines and a pumped storage power plant

In addition to the highest wind turbine in the world with a hub height of 178 meters and a total height of 246.5 meters, three more wind turbines and a pumped storage power plant were built.

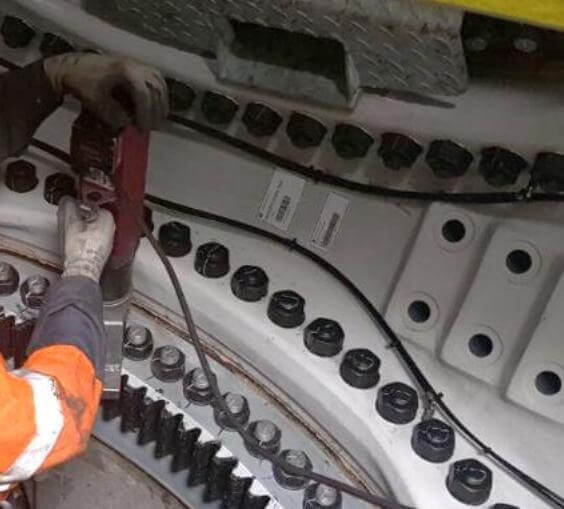

The main challenge in wind installation is to tighten the 104 bolts per wing with a pre torque of 550 Nm plus 180 degrees in the rotor housing where space is restricted.

The world's tallest wind turbine with a total height of 246.5 m, bolted by the alkitronic EF 300 Plus

SOLUTION

"We use the alkitronic EF 300 Plus for several applications. In the green energy storage facility we mainly used it to tighten the rotor blades. Since it is small and easy to handle, it is very well suited for bolting connections in confined spaces", explains Thomas Schott, site manager of Max Bögl Wind AG.

The alkitronic EF 300 Plus in use at the rotor blade bolting (Image: alkitronic)

With the electric torque multiplier, bolting connections can be executed much faster compared to hydraulic systems. Furthermore, no displacement of the pumps and hydraulic hoses is necessary. This mobility plays a decisive role, especially in cramped conditions in the rotor housing. The torque/angle procedure made it possible to tighten all 1248 bolts of the four wind turbines with a torque of 550 Nm plus 180 degrees.

One of the wind turbines under construction. (Image: © Max Bögl Wind AG, photographer: Holger Hessenthaler)

The pilot project in Gaildorf makes a contribution to the declared energy goal of emission-free power generation by 2050 and is an investment in our common future. Therefore, it will be fostered by the German Federal Ministry for the Environment, Nature Conservation Building and Nuclear Safety with 7.15 million euros.

Attaching the rotor blades (Image: © Max Bögl Wind AG, photographer: Holger Hessenthaler)

As part of the pilot project green energy storage facility, the long-lasting, robust and reliable EF 300 Plus electric torque multiplier has once again proven itself in wind installation. The rotor blades of the wind turbines are optimally bolted.

Bolting connections under confined conditions in the rotor housing (Image: alkitronic)

TECHNICAL DATA OF THE EF

-

Quality bolting according to the torque/angle procedure with the models EF / EFW in version "plus"

-

Innovative motor protection with automatic switch-off to secure the bolting quality

-

Consistent and precise reproduction of the pre-selected torque thanks to smart processor-controlled switch-off electronics

-

Robust and long lasting: motor housing of cast aluminum

-

Safe work in any weather (moisture, rain) thanks to protection class IP 54

-

Specifications: All alkitronic electric torque multipliers with CE-certification. Repeat shut-off accuracy ± 3% for the same bolting application

-

Electrical data: Universal AC Input 100 V - 253 V, frequency 45 Hz - 66 Hz Power max. 2000 W, protection category I, Protection class IP 20 (standard), protection class IP 54 (optional)

FURTHER INFORMATION

Learn more about the project in Gaildorf at http://www.mbrenewables.com/en/pilot-project/

If you have any further questions on alkitronic products and applications or if you are interested in a partnership, please contact us. Our employees and partners at home and abroad will have customized solutions for you. This will let you accomplish your tasks easily and reliably.

- Source:

- alkitronic

- Author:

- Press Office

- Link:

- www.alkitronic.com/...

- Keywords:

- alkitronic, Max Bögl, Gaildorf, storage facility, torque, rotor blades, wind turbine