News Release from SAERTEX GmbH & Co. KG

Wind Industry Profile of

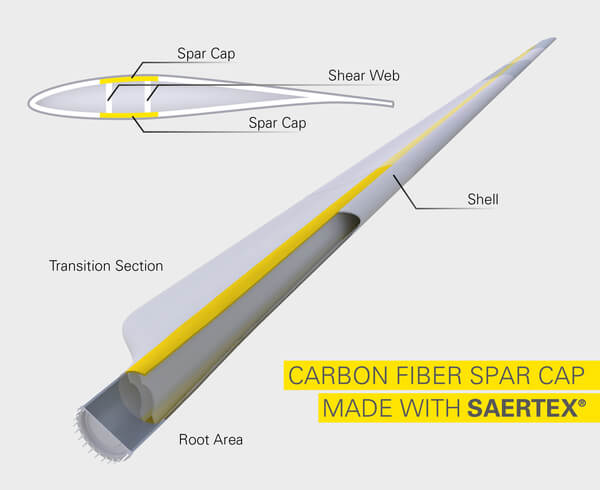

World's largest carbon spar cap made in collaboration with SAERTEX®

In June 2017, a major Chinese wind turbine blade manufacturer successfully finished the production of an 83.6m blade prototype. A special feature of this blade is it ?s spar cap, which takes up most of the mechanical load. The spar cap is made of carbon fiber to reduce the part’s weight and achieve higher stiffness which is essential for rotor blades of such extreme length.

The blade was designed by WINDnovation. Its spar cap was pre-produced in May and represented a technical challenge because of its length of 80.5m and thickness and a thickness, at its broadest section, of 70mm.

An infusion-optimized carbon fiber UD 618gsm (unidirectional non-crimp fabric) with increased z-permeability material was used from SAERTEX, which had been specially developed for the infusion of thick lay-ups. The latent resin system 3325 A/B from CTP AM with optimized viscosity and extended pot-life was also used.

The spar cap was infused in VAP technology with Composyst's VAP membrane which enables degassing of the resin during the entire infusion and eases resin distribution throughout the entire part as well as control of the resin content in the part. This makes the entire process safer.

The infusion process itself took less than 3 hours and was completed without any problems. The following day after curing and demolding, the entire team was very pleased to inspect a near perfect part free of defects. The prototype production was technically supported by SAERTEX, WINDnovation, Composyst, CTP AM and ITD.

- Source:

- SAERTEX

- Author:

- Daniel Stumpp

- Email:

- d.stumpp@saertex.com

- Link:

- www.saertex.com/...

- Keywords:

- SAERTEX, blade, carbon, fibre, prototype