Inside Offshore Wind - Fukushima Floating Offshore Wind Farm Demonstration Project

As the advent of offshore wind energy begins and new technologies find introduction, it seems only logical to provide the Windfair.net community with an insight into one of the most exciting developments and projects in this sector - the Fukushima floating offshore wind farm demonstration project - abbreviated as Fukushima FORWARD.

In doing so, we will take a look at the various aspects of the project, including key technical and enviromental success factors. Our special gratitude is directed at the following organisations and institutions that are participating in the underlying project: The Fukushima offshore wind consortium, consisting of the Marubeni Corporation (Project integrator), the University of Tokyo (Technical advisor), the Mitsubishi Corporation, Mitsubishi Heavy Industries, the Japan Marine United Corporation, Mitsui Engineering & Shipbuilding, the Nippon Steel & Sumitomo Metal Corporation, Ltd., Hitachi Ltd., Furukawa Electric Co., Ltd., Shimizu Corporation and Mizuho information & Research, and funded by the Ministry of Economy, Trade and Industry.

In this project, three floating wind turbines and one floating power sub-station was installed off the coast of Fukushima. The first phase of the project consisted of one 2 MW floating wind turbine, the world's first 25MVA floating substation and undersea cable, and was completed in 2013. In the second phase, two of the world's largest 7MW wind turbines were to be installed before 2015. The aim of this project is to establish a general business-model for floating wind farms and contribute to future commercial projects. The project also provides consortium members the perfect opportunity to gain first-hand experience and know-how on the operation of floating offshore wind farms, which is targeted to be one of Japan's major future export industries.

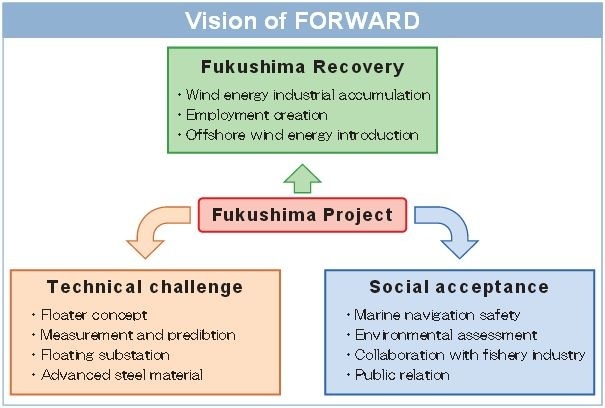

As aforementioned, it is an aim of the Fukushima FORWARD project to help Fukushima to become the center of a new industry, which will create new employment in this region, and as a driver for recovery from the damage caused by the Great East Japan Earthquake in 2011.

Vision of Fukushima Floating Offshore Wind Farm

Two decades have now passed since the first bottom-mounted offshore wind turbines were installed in Europe, with many large scale commercial projects in operation now. Apart from a few floating offshore wind turbines (FOWT) having been installed as a pilot projects in Norway and Portugal, several technical and social questions such as floater optimization and transmission systems on the one hand and environemental and saftey issues on the other, need to be solved before future large scale projects can commence.

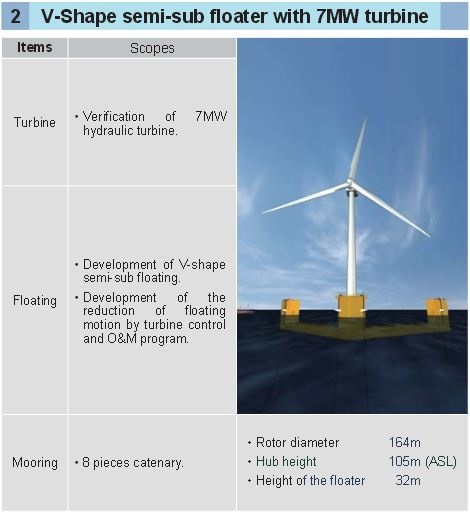

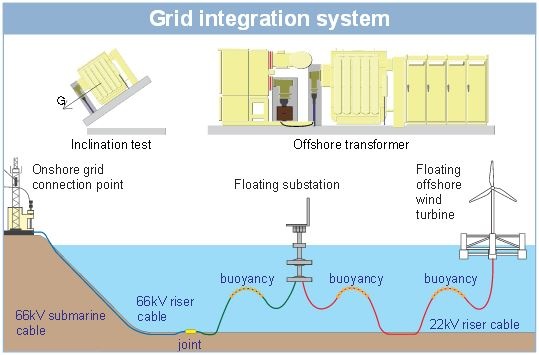

A V-Shape semi-sub floater with the world's largest 7 MW turbine, the world's first 25 MVA floating substation and the 66 kV undersea cable will find implementation in the Fukushima project, whereby economical feasibility of the equipment will be studied. A metocean measurement system that considers floater motion compensation is being developed to evaluate the performance and motion of the FOWT. Furthermore, the characteristics of each floater and wind turbine, as well as the effect of control system on floater motion is being investigated.

In addition, advanced steel materials that are not prone to corrosion and fatigue as well as special construction technologies under severe weather conditions are being developed. The project not only focuses on technical challenges, but also on a collaboration with the fishery industry, on marine navigation safety and environmental assessment, all aspects important for future large offshore floating wind farms.

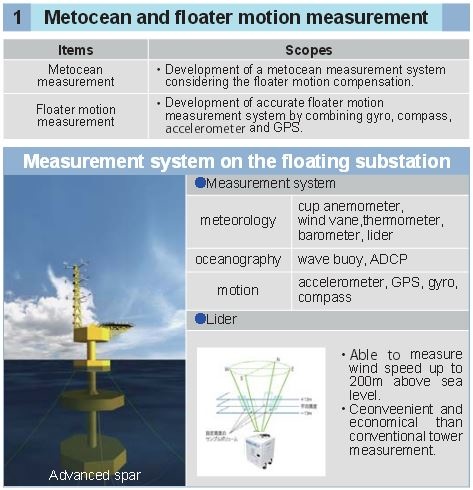

Metocean Measurement and Floater Motion Prediction

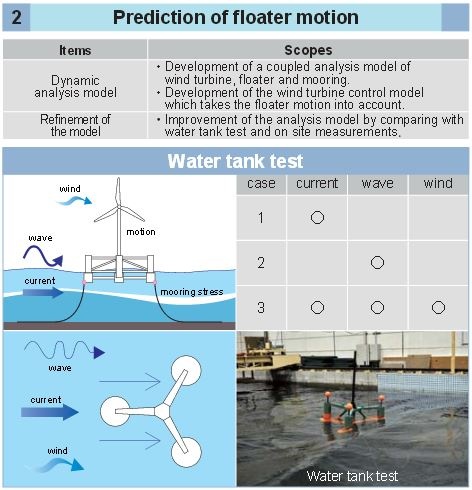

A metocean measurement system is being developed to consider floater motion compensation. Wind speed profiles and wind directions are measured and compared by anemometers on a met mast and a lider on the floater. The motion of the floater is measured by using gyro, compass, accelerometer and GPS, and used for ascertaing the respective motion compensation. Also, in this project a dynamic analysis model of FOWT is developed. The model is improved by comparing the model results with onsite water tank tests and measurement data.

Floating Wind Turbine Technology

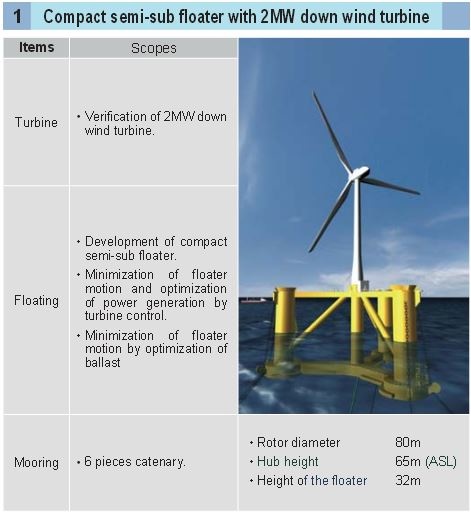

In the first phase of the project, minimization of floater motion, improved safety and power generation efficiency were achieved using a compact semi-submersible floater with 2MW downwind wind turbine. In the second phase, optimization and verification of the design being realised by means of a V-Shaped semi-submersible floater with the world largest 7MW wind turbine. These studies will represent the blueprints for the use of FOWT technology for future large scale offshore floating wind farms.

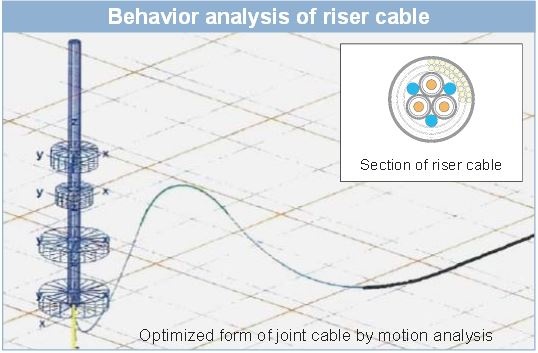

Floating Grid Integration System

An offshore floating transformer system which is both durable and unsusceptible to motion is being developed by evaluating performance against vibration and inclination through shaking table tests. Furthermore, a large capacity water-proof riser cable not prone to fatigue is being developed and optimized via motion analysis. The goal of these studies is to establish the world first floating offshore transformer system against severe metocean conditions.

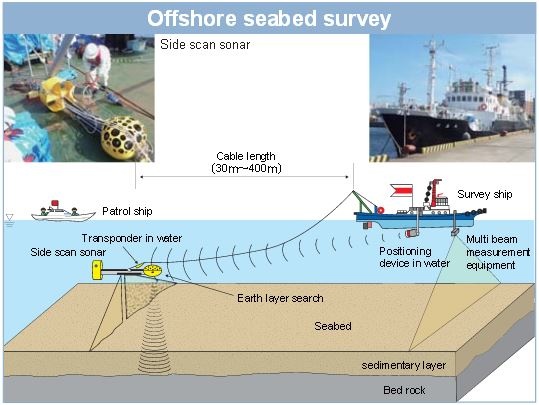

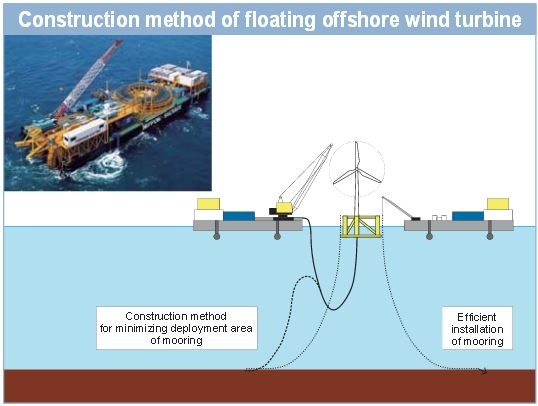

Pre-survey and Construction Technology for Floating Offshore Wind Farm

Optimal construction methods that can be conducted under severe weather conditions, which minimize the impact on the fishery environment are being developed based on preliminary surveys and estimations of meteocean conditions. Furthermore, optimal construction methods for wind farms, consisting of multiple floating wind turbines are in development.

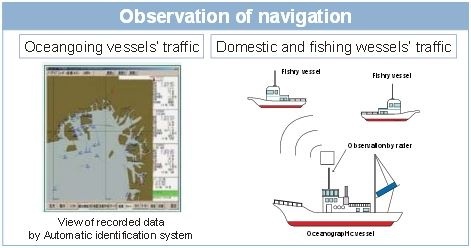

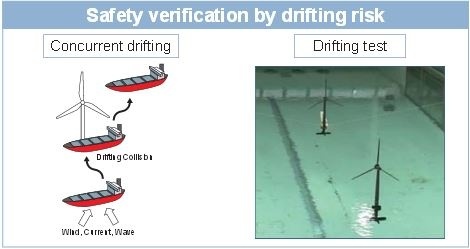

Marine Navigation Safety

For floating offshore wind turbines, collisions between ships or collisions between ships and turbines are an impediment to safety. A collision risk model is therefore being developed and the quantitative risk of collision risk assessed. For this purpose, real-life traffic data in the coastal areas around Fukushim are collected. The collision risk assessment makes it possible to take appropriate safety measures. If mooring is failed by severe storms or accidents, drifting floaters may collide with other wind turbines and ships. A simulation method based on actual response of floating turbines is developed and the consequences of drifting of floating turbines is confirmed.

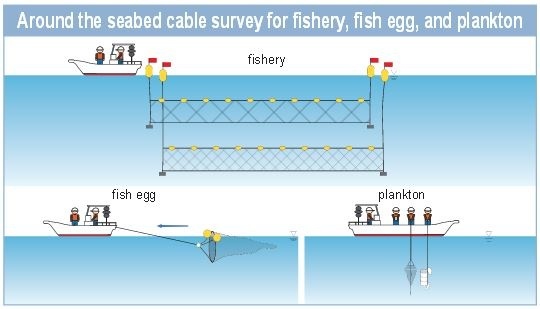

Environmental Impact Assessment

The environmental impact assessment is implemented around the sea where FOWT and seabed cable are installed. The habits of seabirds, marine mammals and fish, as well as the effects of noise, on scenery and radio disturbance will be surveyed and the environmental impact from the turbine and seabed cable installation is being clarified.

If you would like to receive more information on this article, our Newsletter or find out more about what w3.windfair.net has to offer, please, do not hesitate to contact Trevor Sievert at ts@windfair.net.

Please don't forget to follow us on Twitter: w3.windfair.net on Twitter

w3.windfair.net is the largest international B2B internet platform in wind energy – ultimately designed for connecting wind energy enthusiasts and companies across the globe.

- Source:

- © Fukushima Offshore Wind Consortium

- Author:

- Edited by Trevor Sievert, Online Editorial Journalist / by

- Email:

- ts@windfair.net

- Link:

- w3.windfair.net/...