3D printing of large components for the offshore renewable energy industry - inspiration for future cost reductions

Sirris recently published an article (written in Dutch/French language) about the capabilities of additive manufacturing (AM) in the building industry. 3D-Printing of ever larger construction components is no longer exceptional. Other industries can also benefit from this trend, which could bring up advantages in comparison to traditional manufacturing techniques in certain industries. The automotive and aerospace industries for example are already using AM-technology frequently, now also the sector of renewables is taking up the topic for either (offshore) wind energy and tidal energy applications.

Demonstrations have shown that additive manufacturing can lead to cost-savings within the product development cycle, and the technology also makes it easier (and cheaper) to add more functionality into components. Additional costs associated with the use of 3D printing is being compensated as a result.

One early example is the 3D printing of a mold for the turbine blades, used in wind energy and tidal energy applications for example. These components are always expensive to produce because of their uniqueness. Alternative sources of energy production traditionally have to deal with higher costs due to their infant technology stage compared to traditional power generation. Although the costs gaps with traditional energy technologies is decreasing fast, the continuation of the cost reduction effort within renewable energy technology is opening opportunities for additive manufacturing too. Prototyping and development costs for wind turbines can be further reduced for example with the use of additive manufacturing according to the Advanced Manufacturing Office (AMO), part of the US Department of Energy.

Lower development and prototyping costs

Wind turbine blades produced for research purposes can easily be more than 12 meters in length, which is to date to long to be printed in one run. This is why the AMO, together with a number partners, started the research to the use of 3D printed sections of almost 2 meters which can be used to make large molds to produce a full blade. Switching to 3D printing techniques might make it possible to reduce prototyping costs. Moreover, AM-technologies should provide access to production methods that create less waste, have shorter lead times and offer more flexibility at the design stage. Apart from that, the printers are increasing in size and so the opportunities are even greater for tidal and wind turbine blades.

Of course projects like this one require larger 3D printing capacity and the AMO team managed to locate it at the Manufacturing Demonstration Facility (MDF) at the Oak Ridge National Laboratory (Tennessee, USA), which houses a so called ‘Big Area Additive Manufacturing’ (BAAM) 3D printer. The equipment tends to be 500 to 1000 times faster than most other industrial 3D printers and has a building capacity that is many times greater.

BAAM 3D-Printer - Source AMO-US Department of Energy

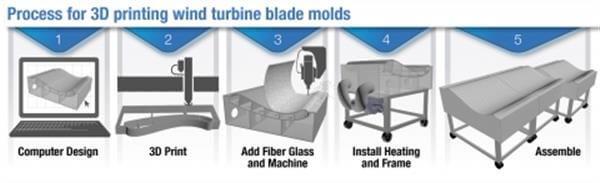

Although this type of 3D printer is not quite capable of working at the actual dimensions required for a full blade, it does provide a realistic overview on how to take on such projects in practice. First of all a CAD model of the blade was designed: in principle a typical blade design from which a mold was made and cut into 3D printable sections, complete with assembly holes and discharge ducts for the hot air. Sections measuring almost two meters were then 3D-printed.

These sections were then given a glass fiber laminated layer and smoothed off. Each mold segment was placed in a frame with a hot air blower, temperature control and thermocouples. The innovative technology using hot air saved energy and eliminated the labor-intensive step of manually installing the heater wires, which are traditionally embedded into the mold. Moreover, the air blowers can be reused for new molds in the future. Once assembled, the gigantic 3D printed mold had an extremely uniform surface, perfect for manufacturing wind turbine blades (or tidal generator blades) at a lower cost when using the traditional production methods. Various blades were produced as demonstrator during this research project using the 3D printed mold.

Process 3D printing blade molds - Source AMO-US Department of Energy

Offshore energy and Sirris expertise

The offshore energy sectors can call on Sirris and benefit from various areas of expertise and high-tech infrastructure to support industrial research and innovation. There’s the OWI-Lab, the RD&Innovation platform for offshore wind energy that brings together companies as well as researchers to carry out specific work in the form of R&D and Innovation. Also, with support from Vlaio (Flemish agency for Innovation & Entrepreneurship) an Innovative Company Network (IBN) for Offshore Energy has recently been set up. This means intensification of support and thematic expansion of the ‘blue energy’ topic such as offshore wind and wave & tidal energy. Component manufacturers of blades on the other hand, can also call on the help of our material and manufacturing experts. With the AM team offering support for the design and developments in Additive manufacturing , and the SLC-Lab for innovating with composite materials.

- Source:

- OWI Lab

- Link:

- www.owi-lab.be/...

- Keywords:

- §D printing, components, renewable energy, cost reduction