News Release from windfair.net

Wind Industry Profile of

Repowering delayed – How REWITEC increases the lifespan of gearboxes

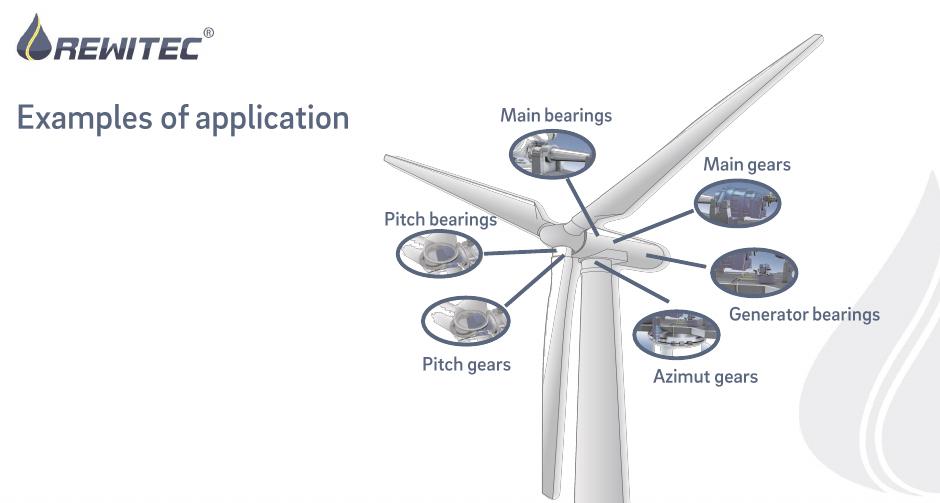

The abrasion and the wear on bearings, gearboxes and similar units is a key issue when it comes to service life and sustainable functionality. Here in particular, the spotlight falls on the aspects of energy consumption, power and operational safety. The German company REWITEC has committed itself to this task and has developed an unprecedented product portfolio. Their nano- and micro-particle-based surface treatment additives are used in so-called tribological systems and are added as an additive to the lubricants of the units.

To present new test results and figures, the company invited interested parties from the wind energy branch to Hamburg, Germany, last week.

The event started with a scientific introduction by Prof. Dr. André Schirmeisen, Director of the Institute of Applied Physics at the University of Giessen (Germany) who told participants about tribology and presented some of the tests that were made.

Subsequently Stefan Bill, CEO of REWITEC GmbH, explained how the additive works: The REWITEC DuraGear® W100 silicon coating is conveyed via a lubricant into the gearbox, bearing or motor and gets in this way to the stressed metal surface. As a result of the crystalline temperatures that arise in live operation, the product’s coating particles react with the molecules of the metal surface and the chemical/physical process is set in motion. On the base of this chemical bonding, the rubbing material surfaces gain a ceramic quality, producing a new, corrosion-resistant metal/ceramic surface. In the process, the material properties in relation to friction and wear improve appreciably, whereas the lubricant properties remain unchanged.

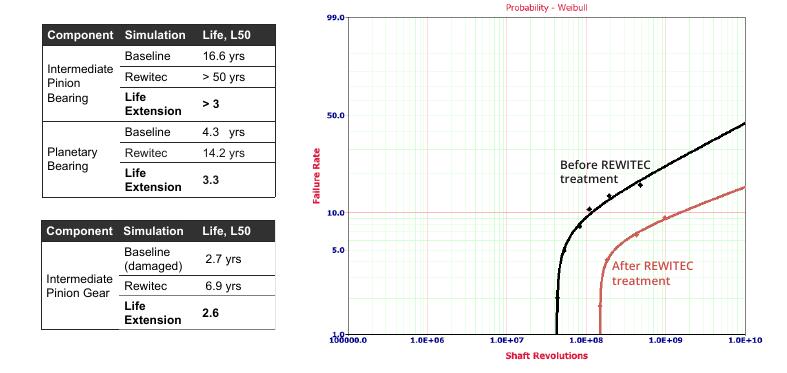

To demonstrate the positive effects of the product based on real figures, REWITEC has teamed up with American company Sentient Science whose employee Wesley Thomas explained the procedure they applied to the additive:

Sentient Science developed a material-science based predictive model of a GE 1.5 SLE Winergy 4410.2. This DigitalClone® gearbox model was used to study the fatigue life impact of W100 treatment on surface damaged bearings and gears. As a result of the measured reduction in surface damage due to the W100 treatment, Sentient’s DigitalClone ® technology predicts that Winergy 4410.2 gearboxes will exhibit a significant improvement in life compared to untreated gearboxes – under field representative operating conditions, REWITEC’s DuraGear ® W100 treatment is calculated to improve bearing life by a factor of 3.3 and overall gear life by a factor of 2.6.

Image: Sentient Science

More tests will follow in the next months with other gear manufacturers to consolidate the test results. However, it can already be said that the use of the additive has an significant life-prolonging effect on the gearbox – the "REWITEC effect" as Bill called it.

This effect resulted – at least for the present companies from the wind energy industry – in a widespread interest in the product of REWITEC, so that the opportunity to do some networking afterwards attracted a large crowd and offered a successful conclusion of the event.

- Author:

- Katrin Radtke

- Email:

- kr@windmesse.de