Using Light to Analyse, Engineer and Optimise

Analyzing the strains, stresses, temperatures and deflections in a bridge during rush hour, a composite aircraft’s wing spar during a storm, or a high-end bicycle during the Tour de France is what allows engineers to predict a structure’s lifetime, increase its safety and optimize its performance. Armed with a complete picture of these quantities from the early design stages to the end of a product’s lifecycle, designers would undoubtedly create safer, stronger, and more efficient engineering structures. 4DSP has teamed up with the NASA Dryden Flight Research Center to create a fiber optic sensing instrument capable of providing this information in real time. This co-developed distributed sensing technology enables monitoring of strains temperature, stresses, out-of-plane deflections, and three-dimensional shape using a small and lightweight package.

Optical sensing has emerged in recent years as an effective solution for characterizing structures in harsh environments. Optical fiber is extremely lightweight, immune to electromagnetic interference and resistant to extreme temperatures and corrosive chemicals. The sensing elements within these fibers are called Bragg gratings. These elements are fabricated using high-intensity UV laser light to locally destroy the silica-oxygen bonds within the core of single-mode optical fiber. The disruption caused by these broken bonds slightly decreases the speed at which light travels through the core, increasing its index of refraction. When this process is done periodically over a short distance along the fiber, a Bragg grating is created. The interesting and useful characteristic of these sensing elements is that they act as selective optical mirrors by reflecting a specific wavelength while allowing all others to pass. The grating’s periodicity is what determines the wavelength that it reflects. Thus, when these fibers are stretched, compressed, or undergo thermal expansion, the periodicity of the grating and its reflected wavelength change proportionally. By using a light source to interrogate them and a detector to sense the reflected signal, Bragg gratings turn plain optical fiber into robust passive strain gages and thermocouples.

Bragg grating sensing systems have been around for over 20 years. Off-the-shelf instruments combining sensing fiber and reflected optical signal demodulation techniques such as wavelength-division multiplexing (WDM) or time-division multiplexing (TDM) are offered by several established manufacturers. However, severe processing limitations associated with these technologies have hindered their widespread adoption outside of the telecommunications industry. For example, WDM requires that each grating on a single fiber reflects its own unique wavelength. To accommodate the expected shifts due to strain and temperature changes, each grating must also be allocated its own wavelength band. This limits the number of sensors available on a single fiber since light sources have limited bandwidth. TDM, on the other hand, allows the gratings to be written at the same wavelength, but this significantly limits processing speed due to the increased number of sensors on a single length of fiber. The low sensor count associated with WDM and low sample rates associated with TDM are useful for other applications but ineffective for large-scale distributed sensing.

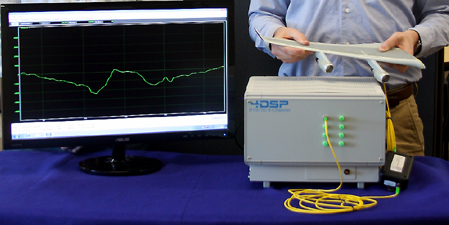

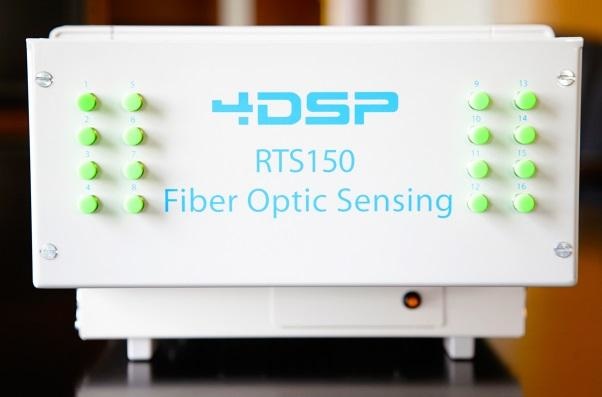

These hurdles have been overcome by technology created in a collaboration between NASA Dryden and 4DSP. Together they have developed and implemented a new processing technique that expands on the capabilities of existing Bragg grating technologies. 4DSP subsequently licensed the patented technology and integrated it into an off-the-shelf product known as the RTS150. This multichannel optical sensing instrument is capable of interrogating a significantly larger number of sensors at higher rates than previous Bragg grating systems. Utilizing the newly developed demodulation technique, engineers can now simultaneously monitor up to 65,536 optical strain gages and thermocouples, each at 100 samples per second. This creates opportunities to solve a vast number of structural problems with distributed optical sensing.

Figure 2: RTS150 Sensing Engineering Strain

The fundamental physical parameters that define the state of a structure are stress and strain. These are the quantities which determine if a bridge will collapse, whether a pressurized tank will burst, or how long an aircraft can continue to be in service. Traditionally, the stresses and strains in large and complex structures such as aircraft and spacecraft are modeled using various finite element methods (FEM) used by engineers to simulate different loading scenarios to determine structural soundness. FEM models are also used to locate critical points to monitor with conventional foil strain gages during testing and operation.

While finite element methods have been a groundbreaking technology in structural engineering, there are still some problems associated with using them. Modern structures are becoming increasingly more complex as new materials and technologies are discovered and introduced to industry. Despite this, FEM models are often simply assumed to be accurate and any validation is done using strain gages positioned at only a few discrete points. Any practicing engineer knows that a lot of unexpected things can occur between any two discrete sensing points. Distributed optical sensing allows engineers to determine precisely what happens over a continuous sensing length and acquire finite element-like experimental data. Fiber can be applied along the entire length of a wing spar, wound around the perimeter of stress-concentrators such as doors and windows, or applied in grids to large planar sections to obtain a far more detailed picture of a structure’s actual behavior. With the ability to sense stress, strain, and temperature at spatial resolutions of one centimeter over entire structural components, this new technology provides the means for FEM models to be fine-tuned, helping to establish the utmost confidence in a model’s accuracy.

Distributed fiber optic sensing also provides new solutions for carbon fiber composites. Their unique fabrication processes allow Bragg grating sensors to be easily embedded within the structure. This technology enables real-time embedded monitoring of highly flexible composite structures from the early design stages to the end of their operational lifecycle. The small spatial resolution and high strain accuracy of optical sensing allows engineers to discover, locate, quantify, and track the various complex failure modes that carbon fiber composites exhibit. Anomalies like delamination between layers, matrix cracking, fiber breakage, and fiber buckling all produce stress and strain concentrations at their origin. Because 4DSP and NASA’s new technology turns the entire length of fiber into one continuous strain gage, these concentrations become evident along the fiber’s output strain profile. As delaminations or cracks propagate under increasing loads or fatigue, the stress concentration point at the crack front can be tracked along the fiber and quantified at each point along the way.

Optical fiber is also resistant to temperatures ranging from cryogenic to hundreds of degrees Celsius. This enables embedded fibers to be monitored during the high temperature cure phase of composite fabrication to determine the through-thickness residual stresses and strains. For these reasons, continuous monitoring of composite structures could be a far-reaching advancement. For example, commercial airlines will always know the state of fatigue damage on critical components, allowing them to fine-tune maintenance schedules and minimize aircraft downtime. Other industries can also benefit from knowledge of the physical state of structures or structural components such as composite rotor blades, foundations, beams, and pressure vessels.

This new technology also enables out-of-plane measurements, which are becoming a critical factor in design and operation as industry continues to move toward lighter and more flexible structures. The majority of sensing instruments in the past have only been able to provide in-plane quantities. Strain gages and traditional fiber Bragg grating systems sense strain only along the primary directions of a structural component. From measurements taken along the length of a beam or in the plane of a plate or shell, mechanical stress and planar deformations are readily obtained. However, there are very few solutions for obtaining distributed out-of-plane measurements of a structure, such as deflections or applied loads, especially during operation. Transfer functions have been developed for use with this new technology which utilize the high spatial density planar strain measurements along a fiber bonded to a structural component. These algorithms yield both out-of-plane deflections and applied loads, all in real time. When applied to a wing spar, engineers can simultaneously obtain the strain along its length and the deflection of the aircraft's wing. This can provide information on flutter; natural frequencies and mode shapes; lifting loads; and moments.

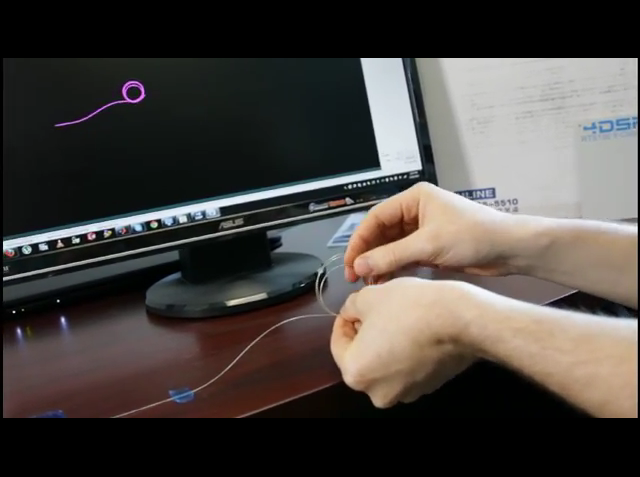

Figure 3: 3D Shape Rendering

Three-dimensional shape sensing of a continuous fiber is another new application enabled by distributed fiber optic sensing. These shape sensors can accurately determine deviations from a straight line, or they can be manipulated into complex shapes with tight twists and bends with radii of less than half of an inch. This unique application can be beneficial to such fields as petroleum engineering, where blockages in oil pipelines can be located and inspected, monitoring of ground movement, or in satellite technology where an antenna is undergoing complex bending in multiple directions. While the 2-D shape sensing solution requires the fiber optic cables to be bonded to an underlying structure, the 3-D shape sensor is an independent entity, which can be used by itself or integrated with an existing structure such as a catheter used for invasive surgery. With a diameter down to 450 micrometers, these sensors can be put through complex, tightly turning tracks like arteries, pipelines and mining boreholes to accurately determine the shape of their path. This makes it possible to record human limb movement far more accurately than current digital image correlation techniques allow. Additionally, the shape of a tether to an underwater vessel can be tracked and used to determine the vehicle’s location and whether or not the umbilical is wrapped around an unseen obstacle.

The future of 4DSP’s optical sensing systems lies in miniaturization and speed. As the size of the interrogation system is reduced, the number of applications for it increases tenfold. Arriving in 2014, the next generation product will be easily capable of fitting within a typical flight instrumentation box. With such a small weight penalty, the future may see every commercial airliner being constantly monitored by distributed fiber optic sensing. Additionally, such systems could be installed in the housing of every wind turbine around the world to continuously monitor blade shapes and structural integrity.

Another leap forward to be taken is an order of magnitude increase in sample rates. While the current rates made possible by 4DSP’s optical sensing instrument have already left many fiber optic sensing technologies behind, the company has their eye on sensing high-frequency vibrations such as those on rotor blades. Paired with the continuous sensing capabilities, high sampling rates would also allow engineers to study stress wave propagation in a whole new way. Distributed sensing offers a unique solution to a wide spectrum of engineering problems and has a bright future indeed.

- Source:

- FBGS International

- Email:

- info@fbgs.com

- Link:

- www.fbgs.com/...